Abstract

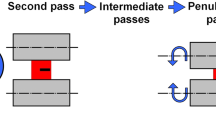

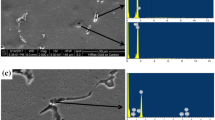

An examination of the influence of rolling path change on the static recrystallization behavior of commercial purity aluminum was performed in the present work. Aluminum strips were cold rolled to a reduction of 50 % under various rolling sequences, i.e. single-pass, double-pass from one direction and with reverse directions, and were then annealed in 290 °C for different durations, while mechanical evaluations such as hardness and tensile tests were used to study the mechanical response of cold deformed and annealed samples. It was indicated that a variation in the recrystallization kinetics of the cold rolled aluminum strips takes place when the rolling path is altered from single to double-pass, and from forward to reverse directions. To express the obtained results and provide a more profound understanding of the flow behavior of rolling samples during deformation processing, combined finite element-dislocation models were taken into account, which were capable of predicting the deformation behavior of the aluminum strips and its consequence on the dislocation structure of the deformed metal. Using the proposed mathematical models, it was found that changing the rolling direction and/or sequence may result in the variation of strain field and dislocation density during cold rolling process, consequently affecting the subsequent restoration phenomena.

Similar content being viewed by others

References

Novikov I (1978) Theory of heat treatment of metals. Mir, Russia

Humphreys FJ, Hatherly M (2004) Recrystallization and related annealing phenomena, 2nd edn. Elsevier, UK

Davenport SB, Higginson RL (2000) Strain path effects under hot working—an introduction. J Mater Process Technol 98:267–91

Gracio JJ (1994) Interaction between thermal recovery and the change in strain path in low carbon steel. Mater Sci Eng A 174:111–17

Choi S, Lee Y, Lee S (2001) A study of the influence of strain path on the microstructure and mechanical properties of low carbon steel using plate and bar rolling. Met Mater Int 7(2):115–121

Higginson RL, Sellars CM (2002) The effect of strain path reversal during hot rolling on austenitic stainless steel. Mater Sci Eng A 338:323–30

Pinheiro P, Monteiro WA, Barbosa R, Cetlin PR (2004) The effect of strain path on the mechanical behavior and dislocation arrangements in the hot working of copper. Mater Sci Eng A 368:280–85

Sakharova NA, Fernandes JV (2006) Strain path change effect on dislocation microstructure of multicrystalline copper sheets. Mater Chem Phys 98:44–50

Gomma E, Mostafa N, Mohsen M, Taha AS (2003) A study on commercial pure Al (1050) after cold rolling at room temperature with various deformation using positron annihilation. J Mater Eng Perform 12(2):190–95

Vieira MF, Schmitt JH, Gracio JJ, Fernandes JV (1990) The effect of strain path change on the mechanical behavior of copper sheets. J Mater Process Technol 24:313–22

Evans RW, Dunstan GR (1971) The hot working and subsequent restoration of commercial-purity aluminum. J Inst Met 99:4–14

Sellars CM (1990) Modeling microstructural development during hot rolling. Mater Sci Technol 6:1072–1081

Abo-Elkheir M (2004) Modeling the high-temperature deformation of commercial pure aluminum (1050). J Mater Eng Perform 13(2):241–47

Kobayashi S, Oh S, Altan T (1989) Metal forming and the finite element method. Oxford University Press, UK

Dixit PM, Dixit US (2008) Modeling of metal forming and machining processes by finite element and soft computing methods. Springer, UK

Avitzur B (1980) Friction-aided strip rolling with unlimited reduction. Int J Mach Tool Des Res 20:197–210

Schey JA (1984) Tribology in metalworking—friction, lubrication and wear. ASM, US

Barlat F, Glazov MV, Brem JC, Lege DJ (2002) A simple model for dislocation behavior strain and strain rate hardening evolution in deforming aluminum alloys. Int J Plast 18:919–939

Honeycombe RWK (1971) The plastic deformation of metals. Edward Arnold Ltd., UK

Gudur PP, Dixit US (2008) A neural network-assisted finite element analysis of cold flat rolling. Eng Appl Artif Intel 21:43–52

Estrin Y, Toth LS, Molinari A, Brechet Y (1998) A dislocation-based model for all hardening stages in large strain deformation. Acta Mater 46(15):5509–5522

Bever MB, Holt DL, Titchener AL (1973) The stored energy of cold work, 1st edn. Pergamon, US

Titchener A, Bever M (1958) The stored energy of cold work. Progr Met Phys 7:247–338

Dieter GE (1988) Mechanical Metallurgy. McGraw-Hill, UK

Acknowledgements

The author wishes to thank Prof. Siamak Serajzadeh of the Department of Materials Science and Engineering at Sharif University of Technology, Tehran, Iran for useful discussions and valuable comments on this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Koohbor, B. On the influence of rolling path change on static recrystallization behavior of commercial purity aluminum. Int J Mater Form 7, 53–63 (2014). https://doi.org/10.1007/s12289-012-1113-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-012-1113-8